Understanding Lead Times

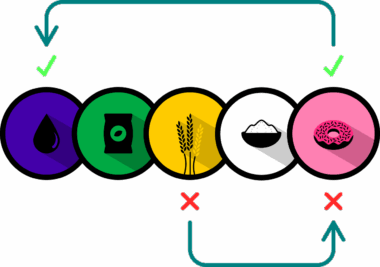

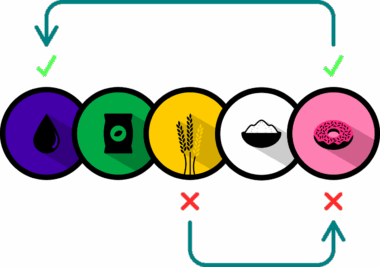

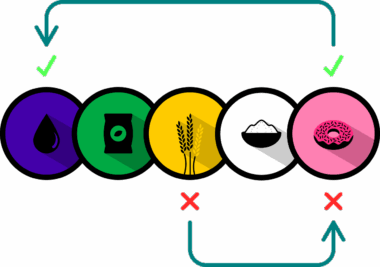

Lead time is a critical factor in supply chain management, fundamentally influencing customer satisfaction and operational efficiency. In simple terms, it refers to the total time taken from placing an order until delivery is completed. An effective benchmarking process for lead times can help organizations identify performance gaps and implement strategies for continuous improvement. To truly benefit from lead time benchmarking, companies should first collect and analyze data related to their order processing duration. This includes measuring individual components that contribute to the overall lead time, such as manufacturing, shipping, and handling. Understanding these factors is essential to identify specific areas for enhancement. Reducing lead times can result in increased customer satisfaction, greater market competitiveness, and improved inventory management. Organizations utilizing benchmarking can easily compare their performance with that of industry standards or competitors, providing a grounds for strategic decision-making. Several methodologies can be implemented to gauge current lead times like Six Sigma and Lean principles. By focusing on waste elimination and process improvement, these frameworks support the goal of achieving optimized lead times and enhanced overall supply chain efficiency.

The Importance of Lead Time Benchmarking

Benchmarking lead times is essential for not only identifying inefficiencies but also seizing competitive advantages within the market. Companies can use benchmarking to align their lead time performance with industry leaders, which enables setting realistic and achievable performance goals. The process involves comparing internal lead times with those of similar organizations to pinpoint opportunities for improvement. When interpreting benchmarking results, it’s important to consider external factors that can impact lead times, such as geographic location, supplier reliability, and customer expectations. Understanding how these variables interact within the larger supply chain context helps form more effective lead time strategies tailored to the business’s specific needs. Additionally, leveraging benchmarking insights can empower companies to streamline their operations. Importantly, sharing best practices gleaned from benchmarking can foster a culture of continuous improvement among stakeholders. By regularly revisiting benchmarks, organizations can evaluate performance over time, adapting to changing market conditions efficiently. Furthermore, lead time benchmarking can guide prioritization of investments regarding resource allocation, thus maximizing overall return on investment while enhancing customer loyalty and satisfaction.

Effective lead time improvement strategies are crucial for attaining operational excellence. One strategy involves employing advanced forecasting techniques that refine demand predictions, enabling more accurate production and delivery schedules. A demand-driven supply chain, integrated with real-time data analytics and automation, can significantly reduce lead times. Organizations can also invest in technology and software solutions that optimize inventory management, coordination among suppliers, and logistics. Utilizing tools like Just-In-Time (JIT) can help in maintaining minimal inventories while ensuring timely replenishments. Moreover, building strong relationships with suppliers is key to improving lead times; fostering collaboration can lead to smoother operations and faster response times. Additionally, continuous training programs can equip employees with the necessary skills to identify bottlenecks in processes and make informed decisions promptly. Regularly reviewing operational procedures is beneficial, as it allows for adjustments that enhance efficiency. Companies should also implement performance measurement systems to keep track of lead time metrics, ensuring that everyone is aligned with improvement goals. This robust approach to improvement establishes a proactive culture that values efficiency and customer satisfaction, ultimately contributing to enhanced business performance.

Another vital strategy is optimizing the supply chain network design. This involves analyzing the entire supply chain structure to identify constraints and potential delays. Employing modeling techniques and simulations can aid in envisioning the effects of changes within logistics, warehousing, and distribution networks on lead times. Companies might find opportunities to consolidate shipments, adjust delivery routes, or even reorganize warehouse locations for better efficiency. These changes can lead to significant reductions in lead time, allowing organizations to respond more rapidly to customer demands. In parallel, enhancing communication across the different stages of the supply chain minimizes misunderstandings and delays. Implementing collaborative planning, forecasting, and replenishment processes improves overall synchronization and efficiency. Additionally, embracing sustainability practices can play a critical role in optimizing lead times. Leaner processes that reduce waste not only improve efficiency but also lower costs, positively impacting lead times. Engaging suppliers in sustainability initiatives can foster improved collaboration and shared objectives for environmental responsibility throughout the supply chain.

Investing in automation and technology solutions is another excellent method for drastically reducing lead times. Automation technologies, such as robotics and AI-driven decision-making, can streamline various processes in the supply chain. warehouse automation solutions can help speed up order picking and processing, resulting in quicker shipment fulfillment. Additionally, incorporating Internet of Things (IoT) devices can facilitate real-time tracking of shipments, reducing the uncertainty associated with lead times. This technology allows companies to monitor inventory levels closely, accurately predict delivery times, and proactively address potential delays. Furthermore, advanced analytics can uncover patterns in data, enabling organizations to make data-driven decisions. Adopting these technological advancements requires a strategic approach to implementation, ensuring that staff is adequately trained to utilize new systems effectively. It also involves establishing clear goals and expectations from these technologies to align them with organizational objectives. Companies that leverage automation and technology can not only enhance lead times but also improve overall supply chain visibility and agility, driving superior customer experiences.

Continuous assessment and adaptation of lead time strategies is essential for sustaining improvements over time. Businesses should establish a robust monitoring system to track key performance indicators associated with lead time performance. Regularly reviewing these metrics reinforces accountability among employees and teams. Utilizing dashboards and performance reporting can help visualize trends and patterns, making performance analysis easier and more meaningful. Implementing a feedback mechanism encourages employees to identify potential challenges that could hinder lead time improvement efforts. Establishing a culture that embraces change and adapts to evolving customer needs fosters long-term results. Moreover, businesses should stay abreast of industry trends that might influence lead times, such as regulatory changes and market fluctuations. Engaging in industry networks and forums can facilitate obtaining insights and best practices for lead time benchmarking and improvement. This knowledge sharing creates a sense of community and collective learning among organizations. In addition to driving internal improvements, participating in benchmarking collaborations with other businesses promotes higher service levels and improved responsiveness across the broader supply chain.

In conclusion, benchmarking lead times presents unique opportunities for organizations to enhance their supply chain performance. By understanding what lead time entails and the importance of continually assessing it against industry standards, businesses can identify weaknesses and seize areas for improvement. Strategies such as optimal supply chain network design, embracing new technologies, and fostering supplier collaboration create a foundation for efficient operations. Furthermore, building a strong internal culture that prioritizes training, communication, and continuous improvement reinforces the significance of measurement and reflection on performance. Organizations should consider the value of leveraging automation and technology, especially in an increasingly data-driven world, to make informed decisions that drive lead reduction. Continuous adaptation and responsiveness to customer needs are key for maintaining competitiveness. Ultimately, companies that invest in robust lead time benchmarking and improvement strategies will reap significant rewards, enhancing customer satisfaction and loyalty while streamlining operations to achieve superior business outcomes.