How AI is Transforming Supply Chain Benchmarking Practices

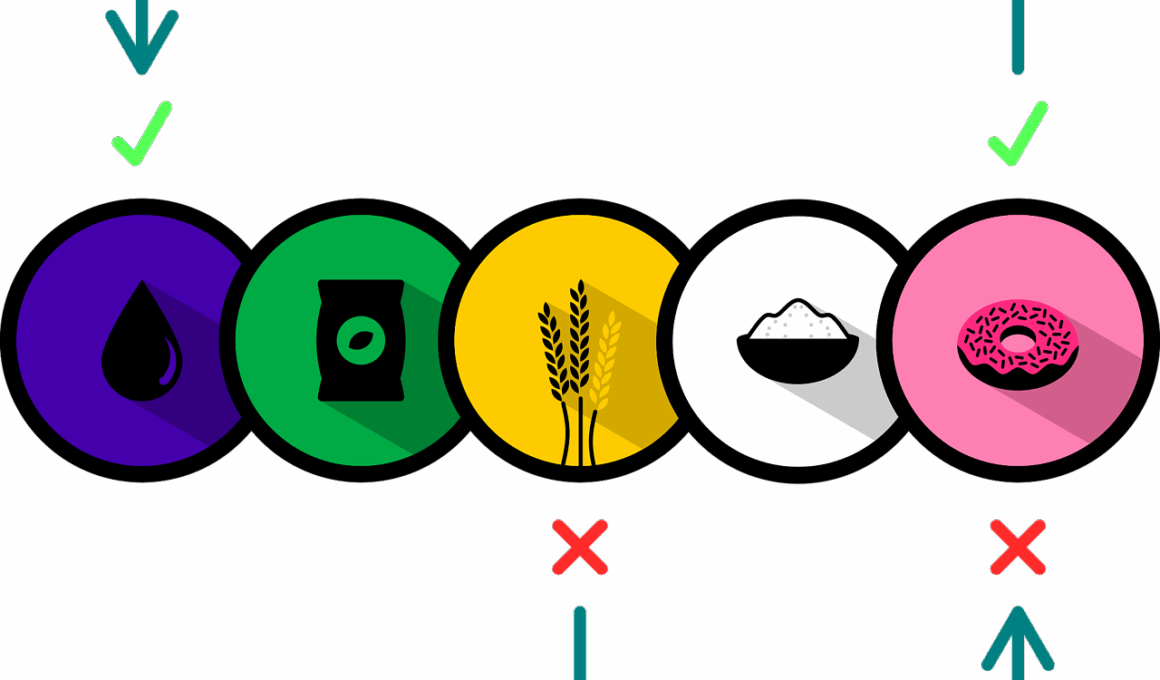

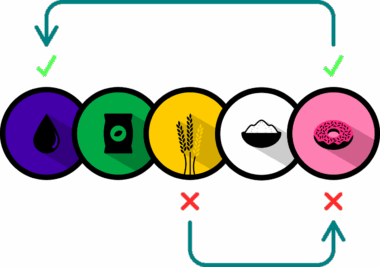

Supply chain benchmarking establishes performance metrics to assess efficiency and effectiveness among competitors. Traditionally, this process relied on historical data, manual comparisons, and sometimes subjective evaluations. The advent of AI has long since transformed this landscape by enabling dynamic assessments and real-time insights. Businesses can now analyze vast quantities of data from varied sources to identify best practices and performance gaps. Utilizing machine learning, organizations can adjust their strategies promptly based on emerging trends. AI algorithms can learn from real-time supply chain data, enhancing predictive accuracy for inventory management and logistics. This real-time approach empowers businesses to be proactive rather than reactive. By leveraging AI, companies can ensure that their benchmarks are up-to-date and reflective of the current market landscape. Furthermore, companies utilizing AI in their benchmarking practices often experience significant enhancements in operational efficiencies. Notably, this technology assists in reducing costs and optimizing resource allocation. Consequently, companies can align their goals with industry standards, paving the way for informed decision-making and strategic growth. AI-driven benchmarks yield an unparalleled advantage in today’s competitive landscape, ensuring organizations do not merely keep pace but lead the industry.

Artificial intelligence significantly enhances data analytics in supply chain management and benchmarking. Organizations increasingly rely on data-driven insights to make informed decisions. AI-driven analytics tools can process enormous datasets quickly, uncovering trends that would be nearly impossible to identify manually. These tools not only track performance metrics but also compare them against industry benchmarks. This capability allows companies to evaluate their position in the market effectively. For instance, AI can assess supplier performance, customer satisfaction, and delivery times, presenting a comprehensive view. Moreover, advanced predictive analytics can highlight potential bottlenecks before they occur, allowing businesses to take precautionary measures. As a result, AI not only aids in understanding historical performance but also promotes proactive measures to enhance efficiency. In addition, organizations using AI-enhanced analytics can solicit feedback more effectively. Collecting and analyzing customer input through AI enables firms to refine their processes continuously. This information ultimately leads to a deeper understanding of customer needs, fostering stronger relationships in the supply chain. Hence, the combination of AI and data analytics serves as a powerful tool for sharpening benchmarking processes and ensuring continuous improvement in operations.

Another substantial advantage of applying AI in supply chain benchmarking is its ability to improve collaboration across various stakeholders. Supply chains typically involve interactions among suppliers, manufacturers, and retailers, making collaboration essential. AI facilitates seamless integration of information between these parties, ensuring that everyone involved operates with accurate, updated data. Improved communication leads to stronger partnerships and ultimately better performance results. For example, AI tools can enable real-time sharing of performance metrics among stakeholders, reinforcing accountability for improving operational efficiencies. Stakeholders can analyze this data collectively, determining areas to enhance through collaboration. Additionally, AI can help standardize performance metrics used across different organizations. A standardized framework allows companies to benchmark against each other more effectively, promoting a fair competitive landscape. This common ground provides valuable insights for best practices and areas ripe for improvement. Moreover, AI’s capacity to analyze diverse data types and formats enhances the benchmarking process significantly. Centralizing data from various stakeholders makes it easier to conduct performance comparisons. Consequently, AI enables a holistic view of the supply chain, fostering a spirit of cooperation among participants committed to excellence in their operations.

Enhanced Risk Management through AI

AI technology significantly contributes to better risk management within supply chain benchmarking. Supply chains are fraught with potential disruptions, whether due to natural disasters, political instability, or economic fluctuations. By implementing AI, organizations can develop more robust risk assessment frameworks that proactively identify vulnerabilities. Machine learning algorithms can sift through historical data to highlight patterns associated with past disruptions, helping firms anticipate future challenges. This predictive capability is invaluable, allowing companies to implement contingency plans based on AI-generated insights. Furthermore, real-time data monitoring enables businesses to respond promptly to any potential issues arising in their operations. AI can analyze external data sources, such as news articles and social media sentiment, to detect emerging risks. The agility offered by AI means that organizations can pivot swiftly when unforeseen issues arise. Firms can also simulate various scenarios to evaluate potential impacts and develop adaptive strategies. Enhanced risk management capabilities lead to greater stability and resilience in supply chain operations. Companies can minimize costly disruptions while ensuring continuity of service. Ultimately, AI not only strengthens supply chain performance benchmarks but also fosters a culture of responsible risk management.

Incorporating AI into supply chain benchmarking practices also enhances sustainability initiatives. As environmental consciousness rises, organizations are under increasing pressure to adopt sustainable practices. AI can help companies measure their sustainability performance against established benchmarks. It can analyze energy consumption, waste management, and CO2 emissions across the supply chain. This level of insight enables organizations to identify areas for improvement and track their progress over time effectively. Additionally, by implementing AI-powered optimization solutions, firms can reduce waste in their processes. Such measures not only benefit the environment but also result in cost savings. Moreover, consumers are becoming more discerning about the businesses they support, favoring those with transparent sustainable practices. Adopting AI for sustainability benchmarking can give companies a competitive edge in this context. Firms can leverage AI to develop personalized marketing strategies that highlight their environmental accomplishments. Demonstrating a commitment to sustainability resonates with eco-conscious consumers. Therefore, AI serves not just as a performance enhancer but also as an enabler of longer-term viability. Its integration into supply chain benchmarking fosters both accountability and meaningful organizational changes toward sustainability.

The Future of AI in Supply Chain Benchmarking

Looking ahead, the role of AI in supply chain benchmarking practices is anticipated to grow even more prominent. As technology continues to evolve, businesses must stay abreast of emerging AI capabilities and techniques. Increased processing power and advanced algorithms will enhance the accuracy and reliability of benchmarking metrics. In the coming years, organizations can expect further integration of AI with the Internet of Things (IoT), creating even more dynamic supply chain landscapes. By combining IoT data with AI analytics, businesses will develop truly responsive and adaptive supply chain systems. This convergence will enable real-time decision-making based on fresh data from multiple touchpoints. Moreover, ethical considerations surrounding AI will rise, prompting companies to implement best practices regarding transparency and fairness. Establishing a robust ethical framework will be key for organizations looking to leverage AI in their benchmarking efforts. Finally, continuous learning will become a crucial aspect of AI-driven benchmarking. As organizations gather more data over time, AI systems will learn and adapt, refining their insights and recommendations. This ongoing evolution fosters a culture of innovation, enabling companies to meet challenges head-on and seize new opportunities.

In conclusion, AI is revolutionizing supply chain benchmarking through enhanced data analytics, collaboration, risk management, sustainability initiatives, and the potential for future advancements. As businesses embrace the transformative power of AI, they will achieve not only operational efficiencies but also foster resilience and adaptability. AI’s role extends far beyond mere performance tracking; it infuses organizations with a strategic mindset aimed at continuous improvement. By analyzing vast quantities of data from diverse sources, AI enables businesses to set relevant benchmarks that evolve with changing market dynamics. Companies leveraging AI can proactively identify and address weaknesses in their supply chains while enhancing their collaborative efforts across all stakeholders. The benefits of AI include a robust understanding of risk factors and the potential to streamline operations. Sustainability initiatives will become more accessible as AI empowers organizations to measure their impact accurately. As we look to the future, supply chains will inevitably become more integrated with AI, arming companies with the best tools to lead in their respective industries. The fusion of AI with supply chain benchmarking heralds a new era of performance excellence and strategic leadership.

References

For a more in-depth understanding of AI’s impact on supply chain management, consider exploring these resources on the subject:

- Supply Chain Dive – AI in Supply Chain Management

- Forbes – How AI is Transforming Supply Chain Management

- McKinsey – The Future of AI in Logistics and Supply Chain

These resources offer comprehensive insights into the synergy between AI and supply chain benchmarking.