The Fundamentals of Supply Chain Auditing: Ensuring Efficiency and Compliance

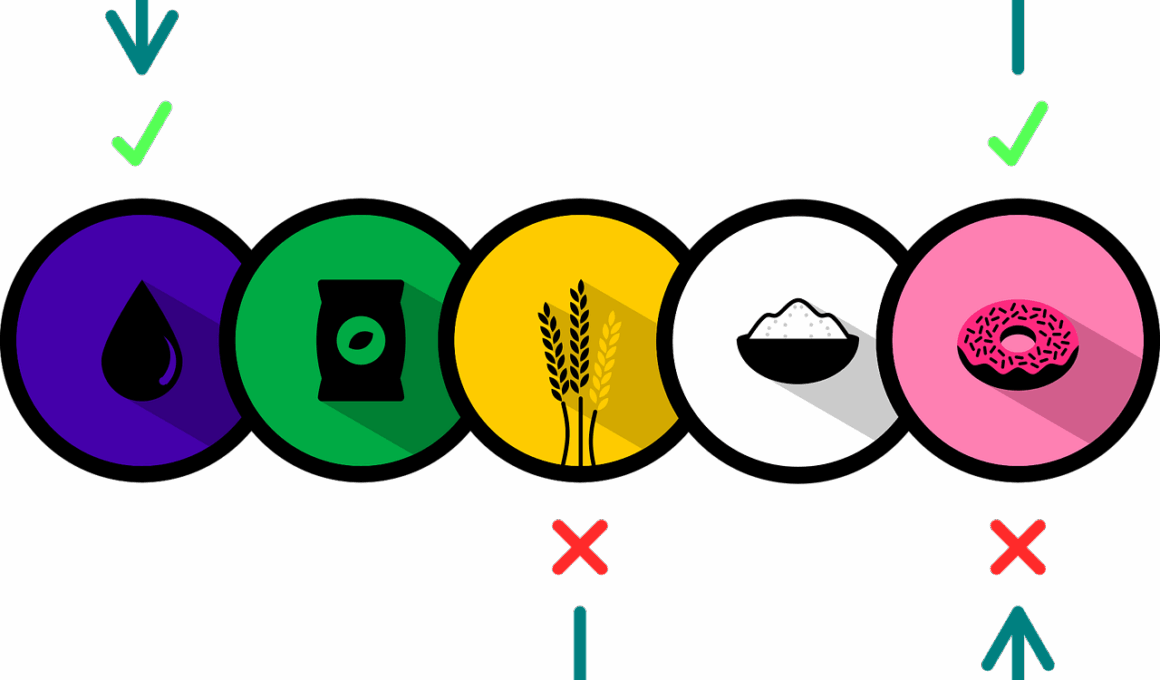

Supply chain auditing is a vital component that ensures efficiency and compliance within organizations. It involves the systematic evaluation of the supply chain processes from procurement to delivery. Auditors assess various aspects including cost management, inventory control, and supplier performance. Through regular audits, companies can identify inefficiencies that impact their bottom line. Compliance with industry standards and regulations is also checked during the auditing process to avoid legal pitfalls. Effective supply chain auditing can help companies streamline operations and reduce waste. By analyzing data and processes, auditors can provide recommendations for improvement. This not only enhances productivity but also strengthens relationships with suppliers. Additionally, supply chain audits foster transparency, making operations more accountable. Efforts to improve through auditing can lead to increased customer satisfaction and loyalty. Organizations that prioritize auditing are more likely to adapt quickly to market changes. Ultimately, successful supply chain auditing contributes to the resilience and sustainability of businesses. When stakeholders understand their roles, supply chain effectiveness increases across the board, leading to a more robust overall system.

The importance of risk management in supply chain auditing cannot be overstated. Companies must proactively identify potential risks in their supply chain to mitigate negative impacts. This may include supplier disruptions, regulatory changes, or geopolitical factors affecting operations. Auditors play a critical role in assessing these risks and developing strategies to manage them effectively. Risk assessment allows organizations to prioritize which areas need the most attention during audits. Furthermore, understanding the specific risks associated with each supplier can lead to more targeted compliance checks. For example, suppliers in different regions may face varied regulations that necessitate tailored auditing approaches. Incorporating risk management practices into the supply chain auditing process enhances overall resilience. It prepares businesses for unforeseen circumstances and strengthens operational continuity. Companies that excel in risk management contribute to smoother supply chains. Auditors also ensure that the risk mitigation strategies are in place and functioning effectively. This proactive approach can save organizations time and resources in the long run. Overall, emphasizing risk management within supply chain audits paves the way for continuous improvement and sustainable practices.

Key Components of Effective Supply Chain Auditing

To conduct effective supply chain audits, organizations must focus on several key components. First, defining clear objectives is essential to guide the auditing process. Setting specific, measurable goals allows auditors to evaluate whether processes are meeting standards. Second, the selection of the right audit team is crucial. Teams should consist of members with diverse expertise across various supply chain functions. This allows for comprehensive evaluation and a nuanced understanding of operations. Third, the methodology employed during the audit should incorporate both qualitative and quantitative assessments. Combining data analysis with interviews and observations provides a holistic view. Fourth, technology integration during audits enhances accuracy and efficiency. Leveraging software tools for data collection and analysis streamlines the auditing process. Lastly, frequent communication with stakeholders is vital throughout the audit. This helps in addressing concerns and allows for real-time feedback that can improve outcomes. Ultimately, these components work together to establish a robust auditing framework. By prioritizing these factors, organizations can achieve thorough audits that contribute to their overall success and compliance objectives.

Another significant aspect of supply chain auditing is determining the correct performance metrics. Metrics provide measurable indicators of effectiveness within the supply chain. They help organizations understand areas for improvement and track progress over time. Common metrics include delivery performance, order accuracy, and inventory turnover rates. Each of these metrics can highlight specific strengths and weaknesses in the supply chain. For instance, low inventory turnover may indicate overstocking or ineffective sales strategies. Consequently, identifying these issues allows for timely interventions. Moreover, relevant metrics establish accountability among teams. When performance is closely monitored, employees are motivated to meet or exceed goals. Regularly reviewing metrics during audits ensures awareness across the organization about performance trends. Additionally, benchmarking against industry standards can shed light on competitive positioning. This helps organizations understand where they stand relative to peers. Using metrics effectively leads to informed decision-making and enhances operational capabilities. Organizations are empowered to innovate and optimize processes, resulting in lower costs and improved customer experiences. In the long run, performance metrics fuel continual enhancement within the supply chain.

The Role of Compliance in Supply Chain Auditing

Compliance is an integral part of supply chain auditing that mandates adherence to laws and regulations. Organizations must ensure that suppliers operate within legal frameworks and industry standards. Auditors assess compliance across various segments such as labor practices, environmental regulations, and safety requirements. This step is crucial as non-compliance can lead to significant penalties and reputation damage. Regular audits help identify gaps in compliance, which can then be addressed proactively. Furthermore, fostering a culture of compliance among suppliers involves training and awareness initiatives. Engaging suppliers in the compliance process not only mitigates risks but also enhances cooperation. Auditors can recommend necessary changes to operations or policies to ensure adherence. Additionally, employing third-party audits can provide an unbiased perspective on compliance efforts. This external review can help maintain credibility in the supply chain. Companies that prioritize compliance benefit from improved relationships with regulators and clients. They also position themselves favorably in competitive markets. In essence, supply chain auditing serves as a safeguard against non-compliance that could jeopardize business viability.

Implementing technology during supply chain audits can dramatically enhance the efficiency of the process. Advanced tools enable auditors to gather data more swiftly and with greater accuracy. Importantly, technologies like artificial intelligence and machine learning offer predictive analytics. These can pinpoint potential issues before they escalate, allowing for timely interventions. Automated auditing platforms can also facilitate continuous monitoring, providing real-time insights into supply chain operations. This shifts the traditional audit focus from a periodic review to an ongoing process. Additionally, utilizing software solutions enhances collaboration between teams. Cloud-based platforms allow for shared access to data and findings, fostering transparency. Data visualization techniques make analyzing complex information much clearer and actionable. Engaging visual aids can communicate findings to stakeholders effectively, leading to informed decisions. Moreover, cyber security measures must be prioritized to safeguard sensitive data during audits. Protecting internal and supplier information is crucial. Thus, organizations that embrace technology not only streamline their auditing processes but also increase their agility in a fast-paced business environment. Overall, technological integration transforms the traditional supply chain auditing landscape and leads to lasting improvements.

Future Trends in Supply Chain Auditing

The future of supply chain auditing will likely see significant changes driven by advancements in technology and evolving regulations. Increasingly complex global supply chains necessitate more sophisticated auditing methods. Furthermore, the convergence of blockchain technology offers promising developments for improving transparency and traceability in supply chains. By utilizing this technology, organizations can create tamper-proof records that facilitate easier compliance verification. Additionally, sustainable practices are becoming central to supply chain considerations. Companies will be tasked with ensuring ethical sourcing and environmental stewardship, which require robust auditing frameworks. Increased regulatory scrutiny on these topics means that auditors will need specialized training in sustainability and compliance standards. The use of data analytics will become more prevalent, providing real-time insights into supply chain performance. Organizations will prioritize agility, demanding audits that quickly address emerging risks and inefficiencies. The implementation of automation will reduce manual tasks, allowing auditors to focus on strategy and analysis. Ultimately, supply chain auditing is poised for transformation, shaping a future where efficiency, compliance, and sustainability are paramount in organizational success. Adapting to these trends is essential for organizations looking to thrive in a dynamic business landscape.

In conclusion, supply chain auditing is a critical process that promotes efficiency and compliance in organizations. As businesses face mounting pressures from regulations and market dynamics, a solid auditing framework becomes increasingly essential. Through effective audits, companies can identify areas of improvement and implement strategies to enhance their supply chain operations. The integration of risk management, performance metrics, and technology will further optimize audits, providing businesses with a competitive edge. Additionally, by ensuring compliance with industry regulations, organizations safeguard their reputation and foster trust with stakeholders. The future of supply chain auditing holds exciting prospects, especially with the introduction of advanced technologies. As organizations adapt to emerging trends, continuous enhancement of auditing processes is vital for success. Suppliers and manufacturers must collaborate to facilitate seamless audits that strengthen overall supply chain robustness. Ultimately, the commitment to quality audits reflects an organization’s dedication to excellence and operational integrity. Therefore, sustaining a culture of accountability and continuous improvement will lead to long-lasting benefits. Companies that view supply chain auditing not merely as a regulatory obligation will likely stand out in the marketplace.