Quantifying the ROI of Supply Chain Analytics Solutions

Supply chain analytics has become critical for businesses aiming to improve their operational efficiency. As the global market grows increasingly competitive, firms are leveraging data to enhance decision-making processes. By analyzing historical data and forecasting trends, companies can optimize inventory levels, minimize costs, and enhance customer satisfaction. This strategic approach helps firms quantify the return on investment (ROI) associated with implementing analytics solutions. Understanding the ROI requires analyzing increased revenue, reduced costs, and improved service levels resulting from analytics-utilized strategies. A robust analytics system allows companies to evaluate performance metrics clearly and informs future investments strategically. Understanding how analytics can impact supply chain operations helps establish clear KPIs for measuring success. Companies must adopt a holistic approach to ensure that analytics tools are effectively integrated into their supply chains, thereby maximizing ROI. Ultimately, a strong understanding of analytics can lead to a competitive advantage, allowing businesses to stay ahead in today’s fast-paced environment. This article delves into the various components involved in measuring the ROI of supply chain analytics solutions, outlining key considerations and best practices for successful implementation.

The first step in quantifying ROI is identifying the specific measurable outcomes organizations expect from implementing analytics tools. These may include enhanced visibility into supply chain operations, which leads to proactive decision-making. Factors such as reduced lead times, lowered inventory costs, and improved customer satisfaction are crucial metrics to consider. Organizations must produce a comprehensive baseline to demonstrate pre-implementation performance levels. By assessing these baselines, companies can calculate the incremental benefits derived from analytics solutions over time. Furthermore, it’s essential to align the outcomes of analytics with the company’s overall business strategy, ensuring that every actionable insight contributes to broader organizational goals. Regularly reviewing these objectives can help in assessing progress and identifying areas for improvement. Companies should document all analytical processes and their corresponding results to maintain accountability and transparency. This documentation also allows decision-makers to conduct informed discussions on funding future analytics initiatives. Best practices suggest maintaining close communication between supply chain and analytics teams for a synergistic effect. Leveraging these insights effectively will further ensure alignment, maximizing the overall impact of analytics on supply chain performance.

Key Components of ROI Analysis

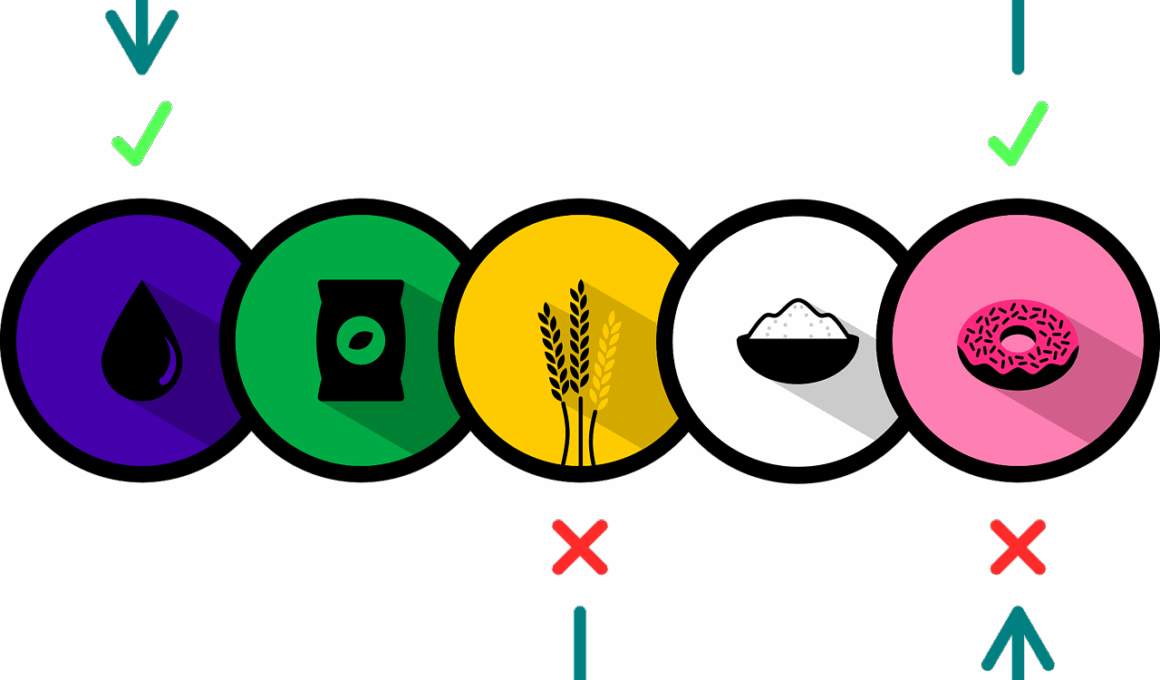

Understanding the main components of ROI analysis is pivotal for businesses integrating supply chain analytics solutions. The analysis typically revolves around five key areas: cost savings, revenue enhancement, improved efficiency, customer satisfaction, and risk management. First, organizations should evaluate cost savings attributed to reduced operational expenses stemming from optimized logistics and inventory management. Analyses that utilize appropriate models can yield significant insights into expenditure reduction. Secondly, revenue growth can be derived from enhanced demand forecasting and operational flexibility. Companies can respond to market fluctuations with agility, consequently increasing their sales execution efficiency. Thirdly, analytics may result in increased efficiency through automation and streamlined operations, which lead to faster product deliveries and heightened responsiveness. Fourthly, improved customer satisfaction can manifest as metrics like higher Net Promoter Scores (NPS), directly affecting repeat purchases. Finally, risk management through predictive analytics can protect organizations from potential disruptions caused by unforeseen events. Healthier supply chains are inherently more resilient. By delineating these components clearly, companies can pursue actionable insights while quantitatively demonstrating analytics ROI.

Incorporating advanced technology into supply chain analytics can significantly enhance the accuracy of ROI assessments. Machine learning algorithms, for instance, can analyze vast datasets to extract meaningful patterns and forecasts that have traditionally been labor-intensive. These advanced models facilitate predictive analyses that prepare companies for future challenges, enhancing the reliability of outcomes associated with supply chain decisions. Tools such as data visualization software help stakeholders comprehend complex datasets in a user-friendly format. They allow for swift identification of trends and disparities, aiding in more informed decision-making. Moreover, cloud-based platforms allow companies to share analytics across multiple departments, creating a unified view of their operations. Enhanced collaboration and data dissemination lead to quicker responses and adaptation to changes. Organizations must capitalize on these tech advancements to keep pace with competitors leveraging similar tools for enhanced efficiency. To fully harness the potential of analytics solutions, companies must continually invest in staff training and the adoption of best practices. By fostering a culture of data-driven decision-making, companies can ensure sustained success in navigating the complexities of modern supply chains.

The Importance of Employee Engagement

Engagement of employees in the deployment and use of analytics solutions plays a critical role in realizing the ROI of supply chain analytics tools. Employees who understand the analytics process are more likely to actively contribute to its success. Training programs and workshops designed for enhancing analytical skills can empower staff members, making them valuable contributors to the implementation process. Engaging employees also helps in bridging the gap between technical teams and operational staff, enabling a smoother transition to a data-driven way of working. Feedback channels must be established to collect inputs from staff, augmenting continuous improvement processes. As analytics evolve, so too should the collaborative approach, including the suggestions from ground-level employees who interact directly with operations. Cultivating an analytics-oriented culture enhances ownership and commitment among staff. Furthermore, leveraging employee insights can yield unexpected revelations, driving innovative solutions to operational challenges. Encouraging a participatory approach in utilizing analytics leads to a fully engaged workforce that seeks ongoing optimization. Overall, investing in employee engagement translates into a strong foundation for implementing efficient supply chain analytics solutions to maximize ROI.

Evaluating the long-term impact of supply chain analytics on revenue generation is equally essential in quantifying ROI. Firms must assess how analytics-driven decisions affect the bottom line a few years post-implementation. While short-term gains serve as compelling indicators of success, long-term sustenance is what ultimately demonstrates the true power of analytics. Organizations should also consider how these outcomes correlate with wider industry trends over time. Market dynamics can shift, and a sustained analytics framework helps organizations remain resilient. Companies need to analyze performance consistently, utilizing emerging metrics that signal industry shifts. Competitive benchmarking can lend vital insights as firms compare their progress with peers, aiding in identifying best practices for continual growth. Embracing feedback from analytics outcomes can lead to iterative improvements, refining operational strategies over time. Moreover, long-term analytics investments should be monitored, ensuring they align with evolving business strategies. A dynamic approach facilitates adaptability, essential in today’s rapidly changing marketplace. The combination of evaluating both immediate and prolonged outcomes will ultimately solidify the holistic impact of supply chain analytics on organizational success.

Future Trends in Supply Chain Analytics

As the field of supply chain analytics continues to evolve, certain trends appear poised to redefine the landscape. Next-generation analytics powered by artificial intelligence and big data analytics will create significant competitive advantages. These trends allow real-time analysis of supply chain data, improving agility and responsiveness to market changes. Furthermore, the integration of Internet of Things (IoT) devices will facilitate seamless data collection from numerous points along the supply chain, vastly improving decision-making capabilities. Organizations should also anticipate the rise of prescriptive analytics, enabling firms not only to understand potential outcomes but to receive actionable recommendations on optimizing operations. Additionally, collaboration across supply chains will become indispensable as companies recognize the benefits of sharing data with partners for mutual growth. Such collaborations enhance transparency and traceability while simultaneously optimizing processes. Lastly, sustainability will emerge as a critical focus, pushing companies to invest in analytics solutions that improve eco-friendliness. Staying abreast of these trends will empower organizations to leverage supply chain analytics solutions effectively, enhancing their overall ROI and ensuring long-term success.

In conclusion, quantifying the ROI of supply chain analytics solutions involves a multifaceted approach requiring diligent analysis and strategic thinking. Organizations must clearly define their expectations, identify measurable outcomes, and integrate advanced technologies to enhance decision-making processes. Employee engagement is crucial in maximizing the effectiveness of analytics solutions, as is long-term evaluation of impacts on revenue generation. As the landscape continues to evolve, companies must remain adaptable, embracing incoming trends such as AI, IoT, and sustainability. By fostering a data-driven culture and investing in comprehensive analytics frameworks, firms can realize significant improvements in operational efficiency and organizational success. Ultimately, it is this combination of strategic foresight, collaboration, and innovation that will enable businesses to thrive in the increasingly data-driven landscape of supply chain management. Organizations that embrace these principles and practices will not only quantify their ROI effectively but will also pave the way toward establishing a competitive advantage in a crowded marketplace. As analytics adoption grows, the collective insights will empower businesses, reinforcing their capabilities and nurturing future growth.