Benchmarking Techniques for Demand Forecast Accuracy

Demand forecasting remains a crucial element of supply chain management, linking production, inventory, and sales objectives. Accurately predicting future demand enables businesses to optimize resource allocation and avoid excess costs associated with overproduction or stock shortages. One common approach to enhance demand forecast accuracy is the use of benchmarking techniques. By comparing their performance against others in the industry, companies can identify gaps in their forecasting processes and implement necessary improvements. This may involve analyzing data quality, statistical methods, or incorporating qualitative factors that affect demand. Another critical aspect is the alignment of sales and operations, ensuring that demand forecasts reflect realities. This could involve close collaboration between sales teams and supply chain professionals. Furthermore, implementing technology tools such as predictive analytics can significantly enhance forecasting accuracy. These tools utilize vast datasets to uncover patterns, enabling more reliable forecasts. Benchmarking not only aids in identifying deficiencies but also fosters a culture of continuous improvement, encouraging teams to adopt best practices from within their industry. By integrating these benchmarking techniques, organizations can enhance their understanding and accuracy of demand forecasting, which ultimately leads to better service levels and profitability.

Various methods exist to benchmark demand forecasting effectiveness, ranging from basic qualitative assessments to advanced quantitative models. One widely applied technique is comparing forecast accuracy metrics against industry standards, such as Mean Absolute Percentage Error (MAPE). Establishing a clear baseline allows teams to measure their performance effectively. Additionally, conducting competitive analysis can provide insight into how peer organizations achieve higher accuracy rates. Many companies engage in informal workshops or forums to exchange experiences and strategies for improving forecasts. Another powerful benchmarking approach involves time series analysis, which examines historical data patterns, facilitating the identification of trends and seasonality. Organizations can leverage tools like software systems that integrate Machine Learning (ML) algorithms, which enhance predictive capacities significantly. These systems analyze data patterns better than traditional methods. Furthermore, continually revisiting benchmarking data is essential for organizations, as market dynamics are constantly evolving. Keeping track of industry innovations and changes ensures forecasts remain relevant. Regularly updating benchmarking processes also stimulates growth and adaptation, allowing companies to pivot when necessary. By employing diverse benchmarking measures, businesses can enhance their forecasting precision and ultimately ensure a smoother supply chain operation with improved customer satisfaction.

Utilizing Advanced Analytics

To improve demand forecasting through benchmarking, businesses increasingly harness advanced analytics and technology. These analytical techniques enable organizations to sift through vast amounts of data efficiently. Predictive analytics methodologies focus on identifying potential future behaviors based on historical trends. Organizations apply these advanced analytics to forecast demand with greater accuracy than traditional methods. Established statistical techniques such as regression analysis and time series forecasting are often incorporated into modern data-driven strategies. These approaches provide a structured framework for evaluating past performance and making educated predictions. Additionally, incorporating external data sources, such as market indicators and economic forecasts, can further refine demand predictions. Utilizing these insights creates a more holistic view of potential demand impacts. Moreover, integrating business intelligence tools enhances data visibility and equips managers with real-time analytics. This aspect is critical for timely decision-making and minimizing response times. Ultimately, advanced analytics empowers businesses to leverage benchmarking in new ways while driving continuous improvement in forecasting accuracy. By investing in technology and adopting data-centric approaches, organizations improve their forecasting processes while positioning themselves for success in an increasingly competitive marketplace.

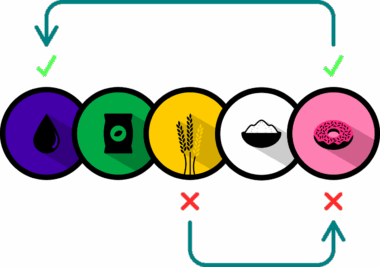

One significant component in the journey toward better demand forecasting is recognizing potential biases. Benchmarking can illuminate these biases, leading organizations to recalibrate their forecasting practices. Systematic errors often arise from overconfidence in certain metrics or failing to account for external factors. For instance, relying solely on historical data without incorporating qualitative insights can lead to flawed predictions. Engaging diverse stakeholders, including sales and marketing teams, can help mitigate these biases. Regular meetings focused on collaborative demand planning allow for the exchange of valuable insights and interpretations of data. Additionally, using control charts assists organizations in visualizing performance consistency across different periods. This visual representation helps detect anomalies and allows managers to adjust strategies accordingly. Another impactful strategy in bias mitigation includes investing in comprehensive training programs for employees involved in demand forecasting. Enhancing skills regarding data interpretation and analytical methods can bridge knowledge gaps and improve results. By embracing a culture of learning and adaptation, organizations can ensure a more inclusive approach to forecasting. Ultimately, addressing potential biases through benchmarking can lead to a firmer foundation for accurate demand forecasting and enhance overall supply chain effectiveness.

Integrating Qualitative Insights

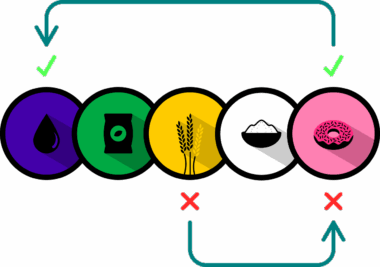

While quantitative data traditionally leads forecast processes, integrating qualitative insights significantly enriches demand predictions. Benchmarking initiatives often highlight the necessity of considering market trends, consumer behavior shifts, and competitive landscape changes. Engaging cross-functional teams fosters better communication and information sharing, enhancing forecasters’ understanding of changing dynamics. For example, frontline sales representatives can provide valuable firsthand insights regarding customer preferences and purchasing trends. Additionally, conducting market research and customer surveys can further better inform demand forecasts. Obtaining these qualitative inputs allows for improved situational awareness and a more responsive forecasting method. Furthermore, adapting surveys and feedback loops regularly can ensure that organizations remain aligned with fluctuating consumer demands. In many instances, understanding the emotional drivers behind purchasing decisions can provide useful context not immediately evident in numbers. Organizations can create more nuanced forecasts by weaving qualitative data into existing models. This adoption of a hybrid forecasting approach can ultimately result in enhanced agility and flexibility in responding to market fluctuations. By appreciating the interplay between qualitative and quantitative insights, businesses can drive more polished demand forecasts and better align their supply chain operations.

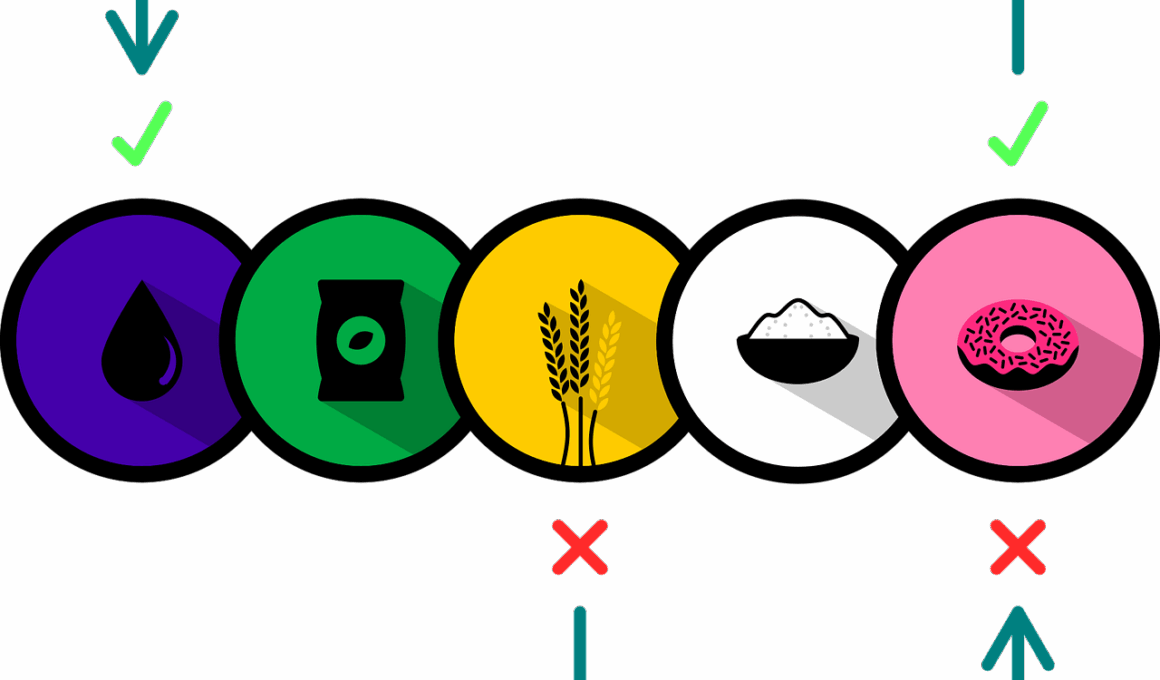

Collaboration with partners is an essential strategy for improving forecast accuracy in the demand forecasting process. As businesses rely on integrated supply chain systems, sharing and managing data across organizations becomes increasingly important. Engaging suppliers and distributors can create a more cohesive network that ensures everyone operates with the same objectives. Regular collaboration meetings allow stakeholders to discuss trends and forecast adjustments based on real-time market signals. Such interactions help manage expectations and avoid stockouts or overstocks. Moreover, embracing collaborative planning, forecasting, and replenishment (CPFR) models fosters transparency, driving joint promotion and planning strategies. This collaboration can elevate demand accuracy across the board, as aligned partners can make informed decisions based on shared data. Additionally, sharing point-of-sale (POS) information can enable more reliable cause-effect analysis around consumer purchasing patterns. Incorporating data-driven insights from key partners may also streamline the development process for new products based on customer feedback. Establishing key performance indicators (KPIs) shared among partners can convey collective accountability. Ultimately, fostering collaborative forecasting efforts can strengthen relationships throughout the supply chain while elevating demand planning performance. Better alignment among partners results in improved service levels and increased customer satisfaction.

Continuous Improvement through Iteration

Further enhancing forecasting accuracy requires an ongoing commitment to continuous improvement, iterating and refining processes based on benchmarking feedback. After identifying areas for growth, organizations must implement actionable initiatives that lead to marked enhancements. Instituting a structured review process encourages teams to evaluate performance and adjust methodologies as they learn. Regularly revisiting demand forecasts to compare against actual outcomes illuminates successes and shortcomings. This analysis creates a feedback loop, ensuring teams remain focused on achieving improved accuracy over time. Additionally, assessing the technologies used within the forecasting process can yield substantial improvements. As the marketplace evolves, so too should the tools organizations utilize. More advanced tools may amplify accuracy while streamlining data processing. Expanding knowledge of algorithms and analytical techniques can help stay ahead in predicting demand. Providing stakeholders with access to real-time data integrations aids quick decision-making. Lastly, fostering a culture that supports experimentation is critical; when employees feel empowered to test new methods or technologies, they can contribute to long-term success. An iterative approach fosters resilience, allowing businesses to embrace changes promptly and enhance demand forecasting accuracy, ultimately benefiting operations and customers alike.

In summary, mastering demand forecasting hinges upon the use of effective benchmarking techniques that encompass both quantitative and qualitative insights. Businesses can learn from peers, evaluate performance metrics, and harness advanced analytics to improve accuracy outcomes. By addressing potential biases, integrating partner collaboration, and committing to continuous improvement, organizations can revolutionize their forecasting methodologies. Employing a blend of rich data sources and engaging teams across functions ensures a holistic understanding of market dynamics. As a result, organizations will position themselves to leverage benchmarking effectively within their supply chain management practices. In this way, improved demand forecasting accuracy can drive optimal stock levels, enhance overall supply chain responsiveness, and ultimately lead to increased customer satisfaction and loyalty. Consequently, investing in robust demand forecasting strategies is not merely a tactical choice but a strategic advantage that organizations cannot afford to overlook in today’s competitive business landscape. Hence, companies must remain vigilant and proactive in their approaches to forecasting, continually seeking innovation and best practices to maintain market relevance. By understanding and applying the aforementioned strategies, organizations can elevate their forecasting capabilities and contribute to superior supply chain performance.