Lean Supply Chain Optimization: Strategies and Benefits

Lean supply chain optimization is a critical approach aimed at eliminating waste and enhancing efficiency in supply chain management. By focusing on value creation and maximizing the flow of products through the supply chain, companies can significantly improve their operations. This process involves assessing existing practices and identifying areas where resources may be wasted. The ultimate goal is to streamline processes and reduce costs while maintaining high-quality standards. Key steps in this methodology may include process mapping, value stream analysis, and the implementation of lean tools such as 5S, Kaizen, and Just-In-Time (JIT) inventory. Companies need to ensure all employees are trained and empowered to identify waste and suggest improvements. Furthermore, lean principles promote ongoing evaluation and adaptation, fostering a culture of continuous improvement. Embracing these techniques not only benefits operational efficiency but also enhances customer satisfaction by reducing lead times and increasing reliability. Businesses that invest in lean supply chain strategies typically see profit margins improve, allowing reinvestment and growth while meeting consumer demand effectively. Strategies that focus on optimizing lead times, inventory levels, and delivery methods are pivotal for success.

Leaders and stakeholders in organizations must understand the core benefits of lean supply chain optimization. One significant advantage is the ability to respond more swiftly to customer needs and market changes. By minimizing waste, companies can allocate resources more effectively and ensure that products are delivered on time. Enhanced visibility throughout the supply chain facilitates improved decision-making, allowing businesses to anticipate demand fluctuations and market trends. Additionally, organizations can benefit from reduced operational costs, which directly contribute to better profit margins. The reduction of excess inventory decreases storage costs and frees up working capital for other initiatives. Moreover, by fostering a culture of collaboration among suppliers, manufacturers, and distributors, organizations can create a more agile supply chain that adapts to changing conditions. Agile supply chains can quickly pivot in response to disruptions like natural disasters or market insecurities. Inherent flexibility translates into a competitive edge, attracting loyal customers seeking reliable and efficient services. The ability to adapt efficiently ensures long-term sustainability in the ever-evolving business landscape, making lean supply chain optimization a business imperative.

Essential Lean Principles and Techniques

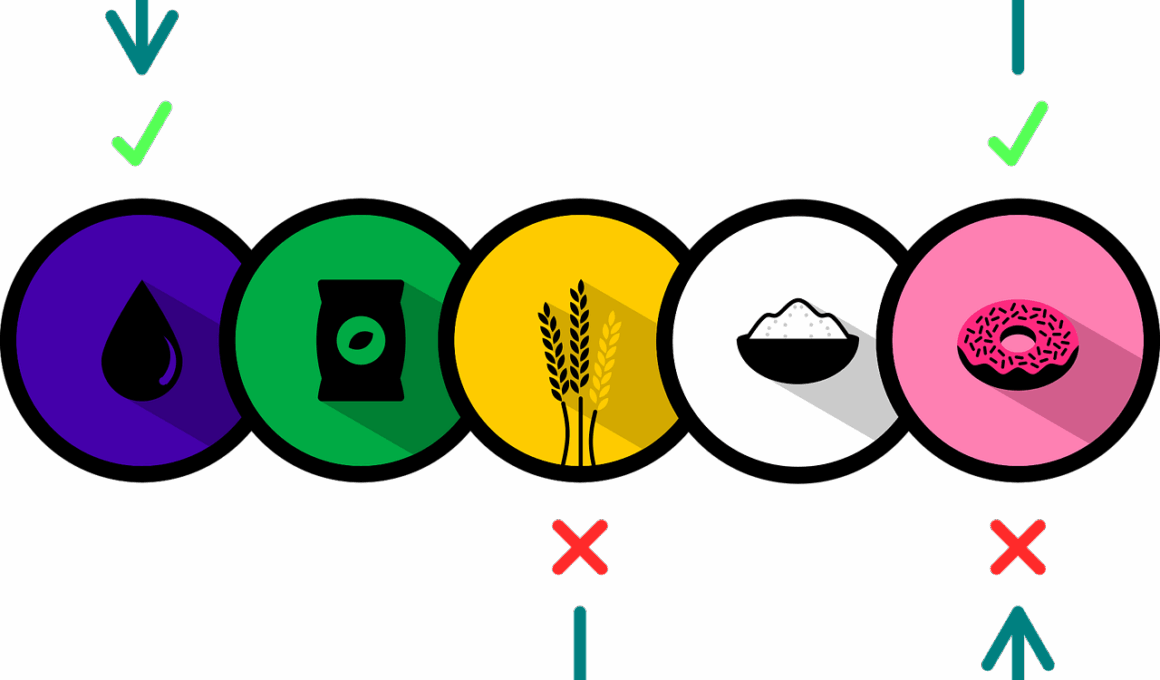

To successfully implement lean supply chain optimization, various principles and techniques can be adopted. One fundamental concept is process mapping, which helps identify each step in the supply chain and highlights areas susceptible to waste. Value stream mapping, for example, allows organizations to visualize the flow of materials and information while pinpointing inefficiencies. Implementing 5S—a methodology focused on organization and cleanliness—ensures that workspaces remain efficient and operational hazards are minimized. Continuous improvement through regular Kaizen events encourages team members to brainstorm and execute small, incremental changes that enhance productivity. Additionally, Just-In-Time (JIT) inventory systems help to reduce excess stock by aligning inventory replenishment with production schedules. Lean six sigma combines lean principles with six sigma practices to achieve quality improvements in processes, addressing defects and variations that lead to waste. Training employees in these methodologies is crucial, fostering engagement and innovation at all levels of the organization. Organizations that successfully incorporate these essentials not only streamline their operations but also enhance employee morale by empowering individuals to actively participate in improvements.

Another critical aspect of lean supply chain optimization is supplier engagement and collaboration. Establishing strong relationships with suppliers creates a unified vision and shared goals, leading to optimized supply chain performance. Regular communication and feedback loops allow businesses to ensure that their suppliers are aligned with lean principles. Engaging suppliers in continuous improvement initiatives promotes a culture of collaboration where shared knowledge and resources can be leveraged effectively. Joint problem-solving sessions allow stakeholders to identify and address potential bottlenecks, fostering mutual understanding and innovative solutions. Additionally, investing in training and development for suppliers can align their practices with the company’s lean objectives. Adopting performance metrics that focus on lean indicators encourages suppliers to enhance their processes and contribute positively to the overall efficiency of the supply chain. Additionally, strategic partnerships with suppliers can enhance flexibility during peak seasons and unexpected market changes. By integrating suppliers into the lean journey, businesses can create a more resilient supply chain that thrives on increased responsiveness and customer satisfaction.

Overcoming Challenges in Lean Implementation

Despite its numerous benefits, implementing lean supply chain optimization can present several challenges that organizations must overcome. One common obstacle is resistance to change within the workforce. Employees may feel threatened by new processes or skeptical about the benefits of lean methodologies. Hence, leadership must communicate the advantages clearly and demonstrate how team involvement directly impacts their roles positively. Effective change management strategies are essential for fostering a culture where employees feel valued and empowered. Training sessions, workshops, and regular updates can build enthusiasm and engagement during transition phases. Another challenge involves aligning systems, processes, and technologies with lean principles. Integration of new tools can seem daunting but is essential for sustaining lean practices. Moreover, some organizations may struggle to maintain momentum and commitment to continuous improvement after initial successes. Establishing a lean steering committee to monitor progress and encourage accountability helps maintain focus. Recognizing and celebrating achievements reinforces the importance of lean practices within the organization. Long-term commitment is vital, ensuring that lean optimization transcends short-term initiatives to become a deep-rooted culture.

Implementing lean supply chain optimization leads to numerous measurable improvements that can transform businesses positively. By reducing waste, companies improve their efficiency and increase profitability. This shift enables reinvestment into innovation and market expansion, allowing businesses to keep pace with competitors. Additionally, enhancing customer satisfaction through shorter lead times and reliable services strengthens brand loyalty and customer retention rates. Improved cash flow resulting from better inventory management leads to enhanced financial health and flexibility, enabling companies to navigate market uncertainties more effectively. As operational efficiencies rise, businesses often experience an improvement in employee morale and productivity, fostering a positive workplace culture centered around continuous improvement. Companies that adopt agile practices can better manage unexpected disruptions, resulting in minimized delays and losses. Moreover, organizations can generate valuable data from lean practices that enable ongoing assessments and adjustments to optimize processes continually. Encouraging transparency in supply chain practices builds trust with suppliers and partners, creating a collaborative ecosystem. Ultimately, the benefits derived from lean supply chain optimization can extend beyond immediate financial returns to establish a sustainable competitive advantage.

Conclusion: The Future of Lean Supply Chains

As businesses continue to evolve and respond to changing market dynamics, the future of lean supply chains holds promise for enhanced efficiency and effectiveness. The integration of technologies such as automation, artificial intelligence, and data analytics into lean practices can further stimulate optimization efforts. These innovations will enable firms to anticipate demand more accurately and streamline operations dynamically. Embracing sustainability within lean frameworks ensures that organizations not only focus on efficiency but also on environmental responsibility. As customers increasingly align with companies that prioritize sustainability, integrating eco-friendly practices within lean operations can bolster brand reputation and loyalty. Future supply chains must prioritize transparency and traceability, enabling stakeholders to verify the origins of products and ensure the quality of their supplies. Collaborative networks will be essential for ensuring seamless transitions between multiple participants in global supply chains. Organizations that successfully adapt their lean supply chain strategies today will emerge as industry leaders tomorrow. By continuously investing in optimizing their supply chain, companies can create resilience that offers a robust platform for growth and innovation.

Cultivating a mindset focused on continuous improvement is vital for businesses embracing lean principles. Employees at all levels should feel empowered to identify inefficiencies and propose solutions, fostering an inclusive environment that encourages experimentation. Regular evaluations of lean practices and outcomes help organizations to adjust their strategies based on real-world data and feedback.