Case Studies: Successful Lean Management Consulting Engagements

Lean management consulting has proven effective across various industries, showcasing profound effects on organizational efficiency. This method focuses on minimizing waste while maximizing value, enhancing processes significantly. For example, in the manufacturing sector, a company adopted lean strategies leading to a staggering 30% reduction in production costs. This intervention included streamlining workflows, implementing Just-in-Time practices, and enhancing employee training. Incorporating technology into these processes often yielded impressive results, allowing for better data-driven decisions. Another success story involves a health care provider that reduced patient wait times by 40% through lean methodologies. By evaluating and redesigning service processes, they eliminated unnecessary steps, increased staff engagement, and improved patient satisfaction. Lean management consulting not only drives cost efficiency but fosters a culture of continuous improvement and innovation. As corporations worldwide face increasing competitive pressures, the adoption of lean strategies becomes not just advantageous but essential. In the coming paragraphs, we will explore more detailed case studies of organizations that exemplify successful lean management consulting engagements and the transformative impact it engendered within their operational frameworks.

Case Study 1: Manufacturing Sector Transformation

In the manufacturing sector, a renowned automotive company engaged lean management consultants to improve their production system. The primary objective was to address frequent production delays and escalating costs previously inhibiting growth. Implementing lean principles, the consultants focused on value stream mapping to analyze existing workflows and identify bottlenecks. By reorganizing the production layout and introducing standardized work protocols, they achieved unprecedented efficiency gains. Additionally, employee training sessions emphasized a culture of continuous improvement, equipping workers with skills to sustain the changes. Over time, the company’s lead time decreased by over 25%, while production output increased significantly. With significant labor savings and material usage optimization, the overall cost savings were substantial. The company noted enhanced morale among staff as their input directly contributed to improved processes. As a result, lean management principles firmly entrenched themselves into the company’s culture. Leadership committed to ongoing lean training for future employees, ensuring a new workforce embraced these principles. Future projects were planned under this framework, indicating the positive long-term implications of lean management consulting on their operations.

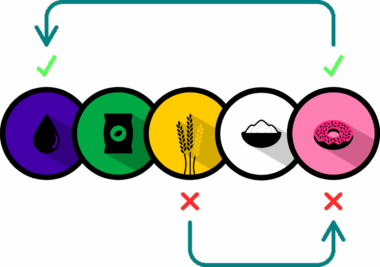

Another significant example in hospitality illustrates lean management’s adaptability across sectors. A major restaurant chain collaborated with consultants to refine their food preparation and service processes. Aiming for improved efficiency and enhanced customer service, the team utilized lean tools such as 5S and Kaizen. Initial assessments revealed unnecessary stock levels and redundancies in food preparation which hindered service speed. Consultants worked closely with kitchen staff, implementing strategies to reorganize workstations, streamline inventory management, and introduce process improvements that reduced waste. Remarkably, average service times decreased by nearly 20%, significantly improving customer satisfaction ratings. Staff engagement and involvement in decision-making contributed to a more cohesive team atmosphere. Sales increased, as positive feedback led to returning customers and word-of-mouth referrals. The adaptability of lean management principles empowered the restaurant to react swiftly to customer demands while optimizing operational costs. Leadership shared this success across branches, encouraging other branches to replicate the model. This case exemplifies how lean management consulting can yield transformative results even in complex service environments, ensuring value delivery is prioritized and sustained in daily operations.

Case Study 3: Healthcare Sector Innovation

The healthcare industry is another prime candidate for significant transformation through lean management consulting. A prominent hospital sought to address persistent patient flow issues and long wait times. In collaboration with lean consultants, the hospital utilized value stream mapping to pinpoint inefficiencies in patient processing. Changes were strategically implemented to reduce bottlenecks, such as reorganizing scheduling practices and optimizing staff roles to meet patient needs effectively. The introduction of daily stand-up meetings encouraged transparency and collaboration, allowing staff to quickly respond to emerging issues. As a result, wait times decreased by over 35%, leading to enhanced overall patient experience and satisfaction. Furthermore, staff frustration diminished as their voices influenced crucial decisions, fostering a collaborative workplace culture. Ultimately, patient outcomes improved with streamlined processes, reducing readmissions and enhancing overall care quality. The success prompted an ongoing commitment to lean practices within the hospital. Continuous training and refinement processes underpinning lean philosophies became crucial to operational success, creating longevity in performance improvements across departments and ensuring enduring benefits for both staff and patients.

In retail, lean management consulting has significantly altered operational strategies for success. One leading department store chain engaged consultants to streamline inventory management and enhance customer shopping experiences. The goal was to diminish excess inventory costs while ensuring product availability for consumers. By employing lean principles, the consultants analyzed stock levels, turnover rates, and customer demand patterns. They recommended implementing vendor-managed inventory systems, enabling real-time stock adjustments and reducing excess holding costs. The projected results indicated that they could decrease inventory by over 30%, directly impacting their bottom line positively. Additionally, reorganizing the store layout led to an enhanced shopping experience for customers, directly increasing foot traffic and sales. Employees were trained to adopt lean practices, fostering a culture of responsiveness and agility. This case underscores lean management’s relevance in addressing unique challenges encountered in the retail sector. Continuous assessments have become routine, ensuring sustained improvements align with evolving consumer expectations. Furthermore, the consumer feedback loop, established to inform inventory decisions, ensures that customers consistently receive what they seek, resulting in increased loyalty.

Case Study 5: Aerospace Industry Efficiency

In the highly competitive aerospace sector, lean management consultants have revolutionized operational frameworks for a leading manufacturer. Facing rising costs and operational complexities, the company required transformative change. Initially, consultants conducted an extensive analysis and identified critical inefficiencies within the production cycles. By implementing a lean transformation, significant adjustments were introduced across diverse workflows, aligning operations with market demand while meeting rigorous safety standards. This included adopting new materials logistics practices and just-in-time production techniques that dramatically cut down on waste and excess costs. The results were transformative; production time reduced by 20%, promoting timely deliveries and improved client relations. Employees were actively involved in redefining processes, leading to heightened job satisfaction and productivity levels. Collaborations among various departments exemplified the synergy generated from lean practices, enhancing overall communication. The successful integration not only bolstered profitability but positioned the corporation as an agile, industry leader capable of navigating complex supply chain dynamics. Continuous improvement protocols underpin all operations, cementing their commitment to innovation and excellence while addressing both internal efficiencies and external customer satisfaction seamlessly.

The field of logistics has also witnessed remarkable narratives of success through lean management consulting endeavors. A prominent logistics service provider faced struggles with delivery times and carriage losses, prompting an examination of their existing processes. Engaging lean consultants, they prioritized value creation by identifying and eliminating non-value-added activities. By standardizing shipping practices and implementing real-time tracking systems, they significantly improved efficiency and accountability. The team established a unique overarching strategy that unified various supply chain segments, bridging gaps between carriers and clients. These changes not only minimized delivery lead times but also significantly reduced costs associated with transportation and inventory management. Enhanced communication across teams fostered a cohesive operational approach while developing a client-focused attitude. Clients reported increased satisfaction attributed to reliable services backed by data-driven insights from the logistics team. As a testament to successful lean implementation, the company’s profits rose dramatically while also expanding their market reach as an industry benchmark. Their experience illustrates the vital role lean management plays in logistics for optimizing efficiency and fostering long-term partnerships.

Conclusions on Lean Management Success

In conclusion, the transformative potential of lean management consulting is profound. Across multiple sectors, from manufacturing to healthcare, companies have experienced tangible benefits resulting from embracing lean principles. Each case study discussed reflects an unwavering commitment to excellence and a relentless pursuit of operational efficiencies. Notably, improved employee engagement and morale further support the contention that integrating lean management practices establishes a positive workplace culture. The intersection of technology and lean methodologies further enhances outcomes, yielding smarter business practices rooted in data-driven insights. These case studies collectively highlight the ongoing necessity for organizations to adopt lean principles in navigating contemporary challenges, particularly in an ever-evolving global market. The adaptability of these philosophies across various sectors demonstrates their universal applicability and enduring relevance. As organizations continue to face market pressures and strive for competitive advantage, embracing lean management consulting will remain an essential path toward operational excellence. Continuous investment in employee training and refinement of processes will cement the success experienced today, ensuring organizations maintain their momentum while paving the way for future triumphs in efficiency and quality of service.